Bin Washing System:

CIP / WIP

Application & Process

The CIP/WIP system is designed for the automatic cleaning, washing, and drying of IBC bins, both inside and outside.

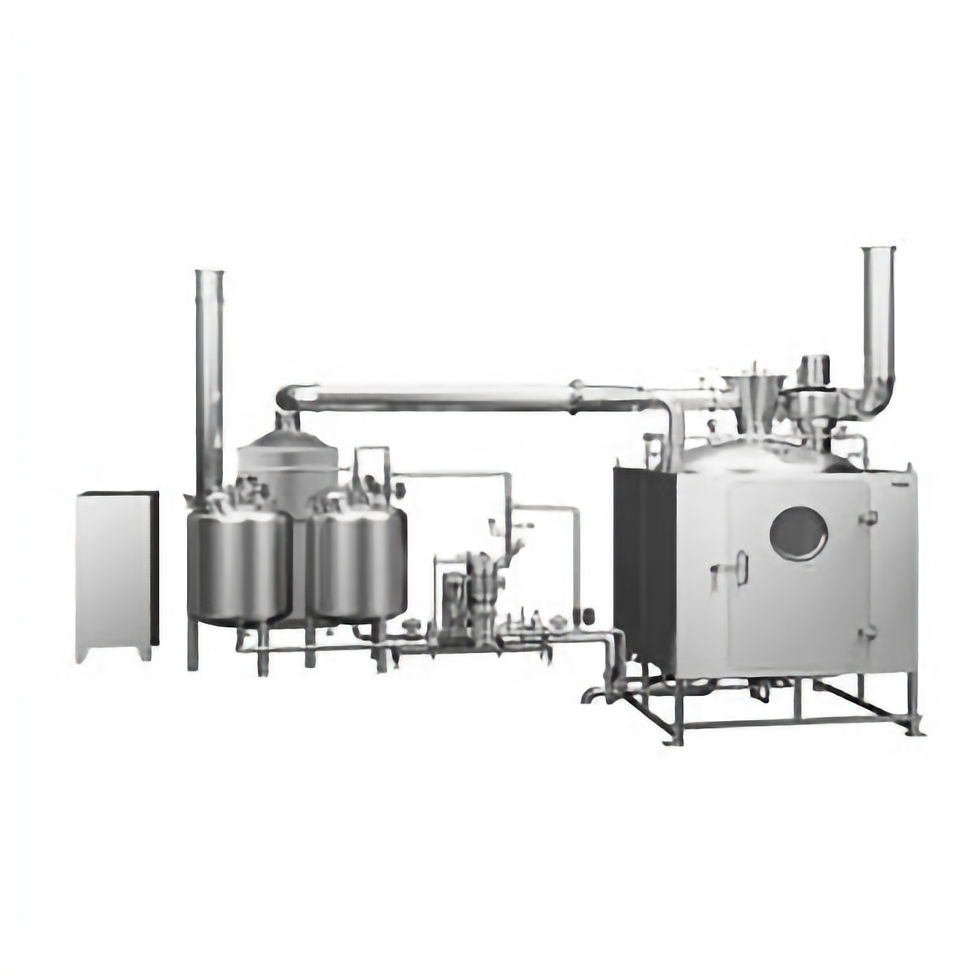

The automatic washing station comprises a closed washing cabinet, a washing system with a pump, a hot air handling system, and a SCADA system with PLC controls and an IPC touch screen.

A used bin is placed in the closed cabinet, and the main entrance door is secured. The washing can occur on either a stationary or rotating platform. The washing cycle times for pre-wash, main wash, final wash, and drying can be set according to requirements. In automatic mode, the wash cycle operates based on the parameters set in the PLC system. Multiple spraying nozzles ensure thorough outer washing from all corners and side walls. A top-mounted spraying nozzle, fitted with a telescopic pneumatic cylinder, cleans the inner surface of the bin by moving up and down during the washing process. The cabinet includes a drain pot for efficient water removal.

After the washing cycles are complete, the bin is dried with filtered hot air from the Air Handling Unit (AHU). Once the bin reaches the set drying temperature, it is ready for safe storage of the next batch.

The closed CIP bin washing system includes a 500-liter purified water vessel, a 25-liter cleaning solution tank, an AHU system, a closed washing cabinet, and a PLC control system with a pressure pump and CIP skid.